Choosing the right Pressure Cleaner for your Industry

Making the correct decision when choosing a new Pressure Cleaner will enable you to clean more effectively saving your company valuable time and money. There also needs to be consideration with the supplier as to their service and spare parts capabilities, and not having to wait weeks on end for that one part that is holding your entire cleaning operation to ransom.

In this guide we offer suggestions for earthmoving, mining, food, farming & agriculture and transport industries.

The Next Generation of Mine Workers are Upskilled at OEM Group

Joining forces with Site Skills Training, one of WA’s leading registered training organisations, OEM Group is part of an exciting initiative to upskill job seekers who are actively looking for work.

“OEM Group understand the potential safety risks of high-pressure cleaning equipment. So, we’re proud to deliver the UHP training course at our facility in Perth. The course is designed to make participants aware of the dangers of using pressure cleaners and in deeming them as competent operators” said Ryan de Mol from OEM Group.

Our Top 12 Pressure Cleaning Accessories

Over the last few years we have had customers use their SPITWATER pressure cleaners for a huge range of cleaning applications from fleet washing, to removing dried concrete from aluminium scaffolding. As a result, a massive range of accessories to improve the performance of your SPITWATER in every application have been developed.

Below we have picked out our favourites, both the under estimated in their impact on productivity, and the lesser heard of.

Choosing the right nozzle for your pressure cleaner: sizes, sprays & maintanence.

Choosing the right nozzle for your pressure cleaner can seem like a daunting task. There are several sizes and spray types to choose from, as well as maintenance required for the nozzle.

This guide will go over why nozzle size is important, what types of nozzle is best for the task, the different types of nozzles that can be used, how often you should replace the nozzle on your pressure cleaner as well as the a high pressure nozzzle.

Undercarriage Cleaning Solutions

At the OEM Group, we distribute a large range of accessories which, coupling with SPITWATER Pressure Cleaners, optimise a variety of different cleaning jobs. One of the most common areas customers come looking for accessories for is vehicle undercarriages.

Vehicle undercarriages can prove difficult to pressure clean for a variety of factors frequently relating to access difficulties.

Introducing the latest undercarriage cleaning solution at OEM Group, the Mosmatic Hurricane Pro and TUW Stationary. Available for purchase now from OEM Group.

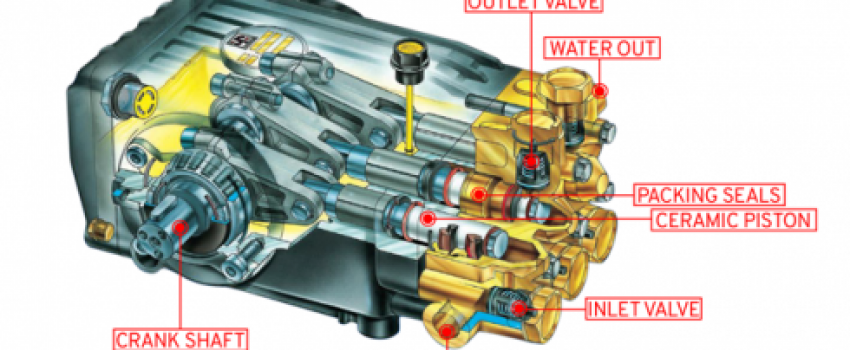

Pump Cavitation: Prevention and Cause

One of the most common problems in pressure cleaners of every make is premature pump failure, most often caused by cavitation.

So, what is cavitation on a pressure washer system?

Cavitation is the formation & accumulation of bubbles in the pumping chamber on your high pressure pump & when these bubbles are put under pressure they collapse or burst which can create tiny but violent implosions inside the water effecting the surrounding parts.

The 2 most common causes of cavitation happening in your pressure cleaner system are internal bypassing and sucking air.